Copper chromite

CAS 12053-18-8

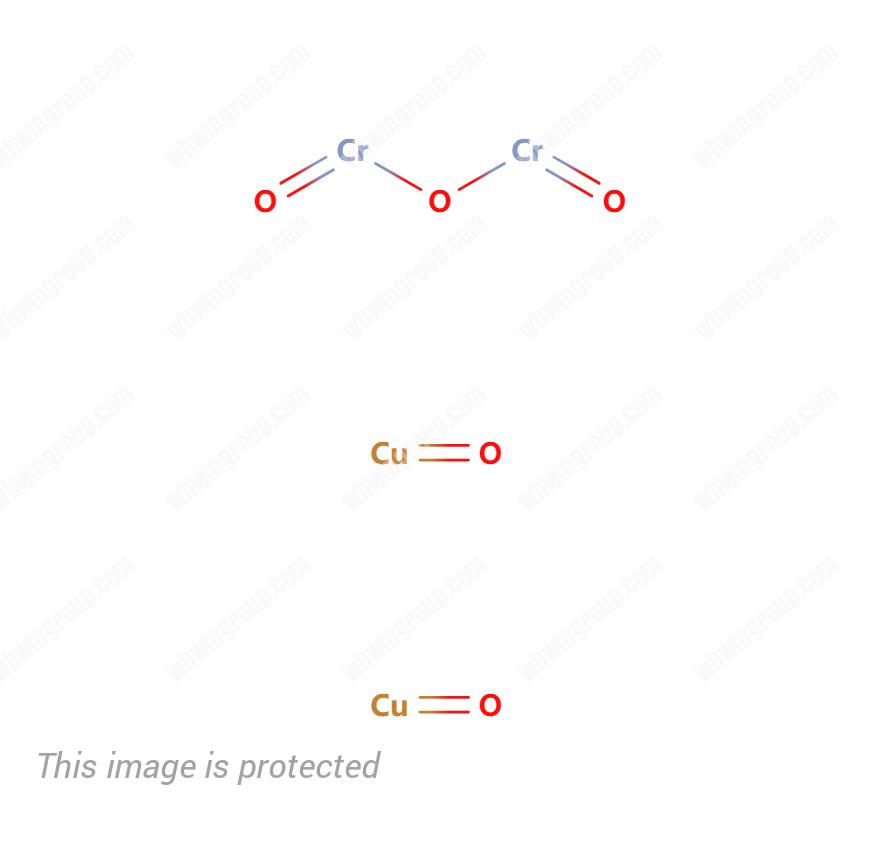

MF: Cr2CuO4

Copper chromite is a black powder and inorganic pigment thatadopts a spinel crystal structure. It can be made by the high-temperaturecalcination of copper(II) oxide and chromium(III) oxide or the thermaldecomposition of copper chromate, which evolves oxygen at higher temperaturesand decomposes to copper chromite.

Description

Copper chromite CAS 12053-18-8 Product Information

| Product Name: | Copper chromite |

| Synonyms: | CopperChromite(Ba/MnPromoted);copper(ii) chromium(iii) oxide;COOPER CHROMITE;oxo-(oxochromiooxy)chromium;Oxocopper;COPPER(II) CHROMITE;COPPERCHROMIUM OXIDE;COPPER CHROMITE CATALYST |

| CAS NO: | 12053-18-8 |

| Molecular Weight: | 231.54 |

| Molecular Formula: | Cr2CuO4 |

| Exact Mass: | 162.85500 |

| InChI Key:: |

JGDFBJMWFLXCLJ-UHFFFAOYSA-N

|

| Hazard Statements: | O,Xi,T |

| Appearance: | Brown to black Powder |

| Purity: | >98% |

| Storage: | Sealed in a cool, dry environment |

copper chromite uses

Copper chromite is primarily used as a catalyst forhydrogenation reactions because of its ability to hydrogenate functional groupsin aliphatic and aromatic compounds selectively. Industrially, copper chromiteis used to reduce furfural to furfuryl alcohol and butyraldehyde to 1-butanol,partially reduce conjugated dienes to monoenes, and selectively reduce carbonylgroups in vegetable oils. This CuCr catalyst is studied for a variety ofcatalytic applications including converting the hydrogenolysis of cellulose.It is also used as a catalyst for combustion to help control burn rate and as alight-absorbing pigment.

copper chromite reduction and passivation

The copper chromite catalyst is used in the reduction of fatty esters into higher alcohols. In this reaction the copper chromite catalyst, CuO/CuCr2O4*, is reduced to Cu/Cr2O3* by hydrogen. In this reduction a part of the water formed is adsorbed onto the catalyst and gives Cu/Cr2O3.

The easiest way to passivate your copper items is simply by exposing them to the elements. Leave them outside for somewhere between four and eight weeks, then check to see whether a dull blue-green patina has begun to form. This colouring actually helps to prevent further corrosion from forming.

copper chromite synthesis

Copper chromite is produced by thermal decomposition of one of three substances. The traditional method is by the ignition of copper chromate:

2CuCrO4 → 2CuCrO3 + O2.

Copper barium ammonium chromate is the most commonly used substance for production of copper chromite. The resulting copper chromite mixture produced by this method can only be used in procedures that contain materials inert to barium, as barium is a product of the decomposition of copper barium ammonium chromate, and is thus present in the resulting mixture. The by-product copper oxide is removed using an acetic acid extraction, consisting of washing with the acid, decantation and then heat drying of the remaining solid to yield isolated copper chromite. Copper chromite is produced by the exposure of copper barium ammonium chromate to temperatures of 350-450 °C, generally by a muffle furnace:

Ba2Cu2(NH4)2(CrO4)5 → CrCuO3 + CuO + 2Ba + 4H2O + 4Cr + N2 + 6O2.

We are Chinese professional supplier of copper chromite for sale.Welcome to inquiry!

Reviews

There are no reviews yet.